GHD announced a partnership with Pacific Gas & Electric Company to provide preliminary engineering design services for a H2/natural gas blending project, named Hydrogen to Infinity (H2∞).

At the Canadian Hydrogen Convention, Edmonton International Airport and Hydra Energy announced the signing of an MoU to deliver North America’s first airside H2-diesel fleet.

Sasol ecoFT has signed a letter of intent with Uniper to investigate the possibility of establishing an industry-scale production facility for sustainable aviation fuel.

Olin Corporation and Plug Power announced the signing of a MoU with the intention to create a JV to produce and market green H2.

Lummus Technology announced a partnership with Braskem to license green ethylene technology.

Maire Tecnimont S.p.A. announces that its main subsidiaries have been granted new awards for approximately €155 MM for licensing as well as engineering, procurement and construction activities.

Tierra del Fuego and MMEX jointly announce the potential development of a green H2 project in the Río Grande area.

Green Hydrogen International and Hydrogen Optimized have signed a MoU for the proposed development of a large electrolyzer manufacturing facility in Texas.

MOL Group has teamed up with Plug Power to build one of Europe’s largest-capacity green H2 production facilities at MOL’s Danube refinery in Százhalombatta, Hungary.

McDermott International has joined a group of industry experts focused on unlocking the potential for a H2-led energy hub located at Bacton, Norfolk, UK.

JAEA and Mitsubishi Heavy Industries will establish a demonstration H2 production project at the high-temperature test reactor in Oarai, Ibaraki Prefecture.

Air Products announced that it is teaming up with World Energy to build a new $2 B major expansion project at World Energy’s Sustainable Aviation Fuel (SAF) production and distribution hub in Paramount, California.

TC Energy and Nikola Corporation are evaluating plans for a H2 production hub in Crossfield, Alberta.

Clear Hydrogen UK Ltd. announced an expansion of its agreement with Proton Technologies. The plan will produce Clear Hydrogen from the UK’s old offshore oil assets and sequestering vast amounts of CO2 as solid carbonate within the same systems.

McPhy has announced that it has finalized its strategic partnership agreement with Hype, key player in light and heavy hydrogen mobility, whose principles were described by McPhy in its press release in December last year.

Wystrach has received a follow-on order worth approximately €1.5 MM (approx. NOK 14 MM) to deliver H2 distribution systems to a leading global industrial gas company.

| Layout | Title | Date | Featured | Meta Title | Meta Description | Sectors | Summary | Content |

|---|---|---|---|---|---|---|---|---|

| pageLayoutLeft | GHD to provide engineering, support services for California H2 project | 5/2/2022 12:46:45 PM | False | GHD to provide engineering, support services for California H2 project | GHD announced a partnership with Pacific Gas & Electric Company to provide preliminary engineering design services for a H2/natural gas blending project, named Hydrogen to Infinity (H2∞). | GHD announced a partnership with Pacific Gas & Electric Company to provide preliminary engineering design services for a H2/natural gas blending project, named Hydrogen to Infinity (H2∞). | GHD announced a partnership with Pacific Gas & Electric Company (PG&E) to provide preliminary engineering design services for a groundbreaking H2/natural gas blending project, named Hydrogen to Infinity (H2∞). This world-class project, being developed in Lodi, California, will address a key data gap in blending H2 into high-pressure natural gas transmission systems. The GHD and PG&E partnership represents the nation’s most comprehensive end-to-end H2 feasibility pilot, which will advance studies of hydrogen as a zero-carbon fuel and renewable energy source for not only PG&E customers but the global natural gas industry. H2∞ is a large-scale demonstration project that will blend H2 and natural gas in a stand-alone transmission pipeline system. It will enable GHD, PG&E and the University of California at Riverside to conduct a complete study of different levels of hydrogen blends in a multi-feed, multi-directional natural gas pipeline system that is independent from its current natural gas transmission system. A world-class training and education facility is also part of the project. The dedicated facility will allow for a controlled and safe study of H2 injection, storage, and combustion of different hydrogen blends in a variety of end uses. The Northern California Power Agency’s Lodi Energy Center power plant is located adjacent to H2∞ and will accept a hydrogen-natural gas blend for electric generation in the Siemens Energy 5000F4 Gas Turbine. Both projects mark the starting point for the creation of the Northern California Hydrogen Hub, which is under development. “This project and the Northern California Hydrogen Hub represent a powerful, impactful, holistic solution to energy and climate change challenges,” added Fred Taylor, project director and GHD Hydrogen Lead. “At complex intersections such as these, GHD can deliver integrated solutions making energy, water and communities sustainable for generations to come.” |

|

| pageLayoutLeft | Hydrogen Europe joins African Hydrogen Partnership | 5/2/2022 1:48:20 PM | False | Hydrogen Europe joins African Hydrogen Partnership | Hydrogen Europe has become the first association member of the African Hydrogen Partnership. | Hydrogen Europe has become the first association member of the African Hydrogen Partnership. | Hydrogen Europe has become the first association member of the African Hydrogen Partnership (AHP). The AHP is the only continent-wide association dedicated to the development of green and naturally occurring hydrogen and fuel cell technology in Africa.

|

|

| pageLayoutLeft | Toyota Motor Europe to supply Toyota fuel cell module to second bus OEM | 5/2/2022 2:14:37 PM | False | Toyota Motor Europe to supply Toyota fuel cell module to second bus OEM | Toyota Motor Europe will supply its Toyota fuel cell module for Daimler Buses’ new city bus, the Mercedes-Benz eCitaro Range Extender. | Toyota Motor Europe will supply its Toyota fuel cell module for Daimler Buses’ new city bus, the Mercedes-Benz eCitaro Range Extender. |

Toyota Motor Europe (TME) will supply its Toyota fuel cell module (TFCM) for Daimler Buses’ new city bus, the Mercedes-Benz eCitaro Range Extender. Daimler Buses is part of Daimler Truck AG. The TFCM2-F-60 is a second generation flat-type module that produces 60kW power and can be easily integrated into the roof of the bus, alongside the battery and H2 tanks. A major benefit of Toyota’s fuel cell technology is that the range of the all-electric bus can be extended in urban traffic to around 400km for the solo bus and up to 350km for the articulated version of the bus. The combination of the battery and the fuel cell as a range extender eliminates the need for intermediate charging on-the-go. TME engineers will support the overall design of the system and the integration of the module into the bus to ensure optimum efficiency, power and service life. The heavy-duty unit’s efficiency results in a comparatively low consumption of hydrogen relative to the power generation. With an integrated voltage converter, the TFCM operates in a voltage range of 450 to 700 volts and most efficiently at around 30kW. In line with its vision of a decarbonized society, Toyota is promoting the application of its H2 fuel cell technology beyond passenger cars to include heavy duty trucks, small delivery trucks, boats and buses. To realize this goal, Toyota is establishing partnerships with several European OEMs that share the same H2 vision. Bringing together all types of hydrogen applications around H2 infrastructure, will support the development of ecosystems where H2 mobility can expand further. "We are delighted to work with Daimler Buses and are pleased to see that our hydrogen powertrain sales activities in Europe continue to expand. Toyota is committed to achieve carbon neutrality and we believe hydrogen is one of the key building blocks of a future decarbonized society," said Matt Harrison, President & CEO of Toyota Motor Europe. |

|

| pageLayoutLeft | C-Job Naval Architects design a new class of liquid H2 tanker | 5/3/2022 9:58:57 AM | False | C-Job Naval Architects design a new class of liquid H2 tanker | C-Job Naval Architects have designed a brand-new class of liquid H2 tanker in partnership with LH2 Europe. | C-Job Naval Architects have designed a brand-new class of liquid H2 tanker in partnership with LH2 Europe. | C-Job Naval Architects have designed a brand-new class of liquid H2 tanker that will revolutionize the renewable energy market. The tanker concept, developed in partnership with LH2 Europe, is a critical element in realizing a green end-to-end liquid H2 supply chain.

LH2 Europe will use the abundant renewable electricity in Scotland to produce green H2 and market it at a competitive price with diesel. The new tanker will transport the liquid H2 to terminals in Germany, with a strategic vision to expand supply to other markets as demand increases. “Hydrogen will be essential to the future of energy. It is up to us how quickly we can make that happen. LH2 Europe aims to have a full liquid hydrogen supply chain ready by 2027,” said Dr. Peter Wells, CEO of LH2 Europe. “We plan to initially deliver 100 tpd of green hydrogen and ramp up production to 300 tpd within three years, depending on demand.” “This tanker design is a key step in providing the infrastructure to make that clean energy future a reality. Current vessels in operation are not able to deliver hydrogen at the scale we expect will be required to meet the needs of the market,” he added. LH2 Europe in collaboration with C-Job Naval Architects developed an initial design for a liquid H2 tanker of 141 meters and a storage capacity of 37,500 m3. Job Volwater, CCO at C-Job, says: “Liquid hydrogen provides unique challenges in ship design and engineering. As a comparison, LNG tankers use ballast water to compensate the loss of weight following delivery to ensure enough draft. As liquid hydrogen is high in volume but 20 times lighter than LNG, this required a unique solution. We have created a trapezium-shaped hull design which creates enough deck space to fit the tanks without the need for ballast. “At C-Job, we have been researching alternative renewable fuels for many years and we are excited to work together with LH2 Europe to apply our knowledge and experience. Not only to realize a cleaner maritime industry but to support green energy across Europe.” The vessel is powered by H2 fuel cells and will be equipped with three liquid H2 storage tanks with total capacity of 37,500 m3, which is enough to refuel 400,000 medium-sized H2 cars or 20,000 heavy trucks. The tanks will have a much lower boil off than those currently used in the maritime industry. The limited remaining boil off will be captured and directly utilized in H2 fuel cells, providing power to the vessel's propulsion systems, resulting in emissions of water only. The vessel itself will have zero greenhouse gas emissions during operations. The ship is expected to be ready and commissioned six months before the first delivery of hydrogen in 2027.

|

|

| pageLayoutLeft | bp to invest up to £18 B in UK energy system by 2030 | 5/3/2022 12:31:06 PM | False | bp to invest up to £18 B in UK energy system by 2030 | bp intends to invest up to £18 B in the UK’s energy system by the end of 2030 to help the country to deliver on its ambitions to boost energy security and reach net zero. | bp intends to invest up to £18 B in the UK’s energy system by the end of 2030 to help the country to deliver on its ambitions to boost energy security and reach net zero. | bp intends to invest up to £18 B in the UK’s energy system by the end of 2030 to help the country to deliver on its ambitions to boost energy security and reach net zero. As one of the largest oil and gas producers in the UK, bp intends to continue investing in North Sea oil and gas, while driving down operational emissions. bp is also in action on a range of lower carbon energy investments in the UK, which are expected to bring jobs and develop new skills and capabilities.

Bernard Looney, chief executive officer, bp said, “We’re backing Britain. It’s been our home for over 110 years, and we’ve been investing in North Sea oil and gas for more than 50 years. We’re fully committed to the UK’s energy transition – providing reliable home-grown energy and, at the same time, focusing on the drive to net zero. And we have ambitious plans to do more and to go faster. Our plans go beyond just infrastructure - they see us supporting the economy, skills development and job opportunities in the communities where we operate. We are all in.” These projected investment figures are in addition to bp’s significant operating spend in the UK. In 2019, prior to the pandemic, an estimated 0.5% of UK GDP was supported by bp’s activities. bp also anticipates paying up to £1 B in taxes for its 2022 North Sea profits, on top of around £0.25 B that it has paid annually in other taxes in the UK in recent years. The UK projects in which bp is looking to invest - and the wider activities supporting them - include: EV charging:

Hydrogen:

CCS:

Aberdeen:

Retail:

|

|

| pageLayoutLeft | New Zealand's first green H2 refueling site to begin construction | 5/3/2022 4:38:38 PM | False | New Zealand's first green H2 refueling site to begin construction | Construction of New Zealand’s first high-capacity green H2 refueling station starts in Palmerston North this week. | Construction of New Zealand’s first high-capacity green H2 refueling station starts in Palmerston North this week. | Construction of New Zealand’s first high-capacity green H2 refueling station starts in Palmerston North this week. The site, adjacent to Palmerston North Airport, is the first of four H2 refueling stations to be developed by innovative Kiwi energy companies Hiringa Energy and Waitomo Group. The partners are building New Zealand’s first nationwide H2 refueling network. Andrew Clennett, CEO of Hiringa Energy, said this is one of the first refueling networks for heavy transport in the world. Financial backing for the project has been provided through investment from Hiringa’s partners, Mitsui and Co (Asia-Pacific), Government funding from EECA and the COVID-19 Recovery Fund, and growth capital from key investors including Sir Stephen Tindall’s K One W One and international funders. Waitomo Group is self-funding its investment in the project because the kiwi business sees H2 as an important step in the transition to lower emission fuels. Waitomo Group Managing Director Jimmy Ormsby said breaking ground at the Palmerston North airport station marks a major milestone for the partnership. “What began as a discussion between two innovative, future-focused Kiwi companies about developing H2 on our existing and new Waitomo Fuel Stops, is now becoming a reality for future Kiwi generations,” Mr. Ormsby said. “Seeing this vision come to life is particularly poignant for me as the third-generation owner of Waitomo, given Waitomo celebrates its 75th anniversary this year. What a way to cement in the transition to a low-emissions fuel future for the fourth generation.” Mr Clennett said heavy transport makes up only 4% of New Zealand’s vehicles, but accounts for more than 25% of our total vehicle emissions. “Green H2 is the key technology that will allow these fleets to stay on the road. It is a mass-market, clean energy solution that can have a real impact on reducing our transport emissions,” Mr Clennett said. “Adding low-emission alternative fuel solutions to our network is a no-brainer. We want to leave a legacy for the next generation of Ormsby’s to continue in our footsteps. The exciting opportunities that green H2 technology offers allows us to deliver on that,” Mr Ormsby said. Specialist H2 equipment for the station has been sourced from Europe. The station will be built next to a Waitomo Group Fuel Stop, servicing petrol and diesel customers. Once operational, H2-powered heavy transport vehicles such as trucks and buses will be able to refuel at the station in similar time to what they are used to. Mr. Clennett said the Palmerston North station will help cement Manawatū’s position as a key logistics hub as transport companies looked for greener fuel alternatives. The partners have been grateful for the help of both the Central Economic Development Agency (CEDA) and the Palmerston City Council. The partners say another three H2 refueling stations are due to begin construction later this year, in Hamilton, Tauriko and Auckland, creating a network servicing more than 95% of New Zealand’s North Island heavy freight routes. More than NZ$50 MM has been invested in the first phase of the project and detailed engineering and compliance work has been completed. Resource consent has been granted for both the Palmerston North and Hamilton sites and applications are in for the Tauriko and Auckland sites. Expansion of the refueling network into the South Island will begin in 2023, with 24 high-capacity refueling stations due to come online across New Zealand in the next 4-5 years to support a growing fleet of H2-powered vehicles. An initial fleet of 20 zero-emission Hyzon H2-powered trucks to support the network has been purchased by TR Group. Built to meet New Zealand regulations and the demanding road conditions, the trucks will be capable of over 600km of range between refueling stops. Hyundai New Zealand is bringing five H2 fuel-cell Xcient heavy-duty trucks to New Zealand, with the second arriving soon. Both Hyzon and Hyundai have received support from EECA funding. |

|

| pageLayoutLeft | Bosch to develop components for H2 electrolysis | 5/4/2022 1:28:50 PM | False | Bosch to develop components for H2 electrolysis | Bosch will assign the development of electrolyzer components to the Mobility Solutions business sector, investing up to €500 MM in this venture by the end of the decade. | Bosch will assign the development of electrolyzer components to the Mobility Solutions business sector, investing up to €500 MM in this venture by the end of the decade. | Bosch is branching out into the development of components for electrolyzers, which use electrolysis to split water into H2 and oxygen. Ideally, the electricity for this purpose is generated from renewable sources such as wind or photovoltaic power, in which case the result is known as green H2.

“We cannot afford to delay climate action any longer, so we aim to use Bosch technology to support the rapid expansion of H2 production in Europe,” said Dr. Stefan Hartung, chairman of the board of management of Robert Bosch GmbH, at the presentation of the company’s annual figure. Bosch will assign the development of electrolyzer components to the Mobility Solutions business sector, investing up to €500 MM in this venture by the end of the decade. Considering energy diversification, the move away from fossil fuels, and the need to reduce CO2 emissions, demand for green H2 is growing rapidly – not only in energy-intensive industries such as steel, chemicals, and heavy-duty freight, but also in private real estate. According to the EU, demand is set to rise to some 10 MMtpy by 2030. Bosch forecasts that the global market for electrolyzer components will increase to a volume of around €14 B over the same period, with Europe set to see the highest rates of growth. To help business and society reduce dependency on fossil fuels and harness new forms of energy, Bosch intends to invest some €3 B in climate-neutral technology, such as electrification and H2, over the next three years. Bosch is to develop the stack – the core component of an electrolyzer As in the fuel cell, the key component of an electrolyzer is a stack, which comprises several hundred individual cells connected in series. In each of these cells, electricity is used to split water into H2 and oxygen. This is the reverse of what takes place in a fuel cell, where electricity is generated by combining H2 and oxygen. In both cases, the chemical reaction is facilitated by means of a proton-exchange membrane (PEM). Bosch is collaborating with several partners to develop a way of combining the electrolyzer stack with a control unit, power electronics, and various sensors to create a “smart module”. With pilot plants scheduled to commence operation in the coming year, the company plans to supply these smart modules to manufacturers of electrolysis plants and industrial service providers from 2025 onward. Using a simple process, Bosch will incorporate a number of these compact modules. They can then be used both in smaller units with capacity of up to ten megawatts and in gigawatt-rated onshore and offshore plants – whether in new-build projects or in existing plants for conversion to the production of green H2. To maximize the efficiency of H2 production and extend the service life of the stack, the smart modules are to be connected to the Bosch cloud. At the same time, the use of a modular design for the electrolyzers is expected to make maintenance more flexible: any scheduled work will require the shutdown of certain sections of the plant only, instead of the entire facility. Bosch is also working on service concepts that will include the recycling of components in order to promote a circular economy. Bosch can use its strengths in mass production and economies of scale Unlike many of the electrolyzer components currently on the market, the Bosch smart modules will be mass produced. As such, the manufacturing operation will generate economies of scale. “Two key factors are involved in ramping up H2 production: speed and cost,” Heyn said. “This is where we can play to our strengths, thanks to our expertise in mass production and our automotive know-how.” Bosch is now planning to start volume production as quickly as possible at several European locations. These include Bamberg and Feuerbach (Germany), Tilburg (Netherlands), Linz (Austria), and České Budějovice (Czech Republic). Bosch portfolio expansion will safeguard jobs The ongoing transformation of the automotive sector presents a huge challenge for the industry. As ever, Bosch’s response here is to innovate. In entering a new field of business – one that will add a nonautomotive wing to its mobility solutions business – the company is seizing the opportunity to further safeguard employment. In the coming years, this expansion into electrolyzer components is expected to create work for hundreds of associates. “In fact, we’re doing three things at once,” Heyn said. “We’re making an important contribution ecologically, economically, and socially.” Bosch is working on mobile and stationary fuel cells Bosch firmly believes in H2 as a future fuel and is also working on both stationary and mobile fuel cells. One intended use for the former is as small, on-site power plants for cities, data centers, shopping malls, business parks, and as charge spots for electric vehicles. Bosch plans to use mobile fuel cells to facilitate the climate-neutral shipping of goods and commodities, initially by truck. The company’s portfolio of vehicle-related products in this field ranges from individual sensors to core components such as the electric air compressor, the stack, and complete fuel-cell modules. Production is expected to start this year. |

|

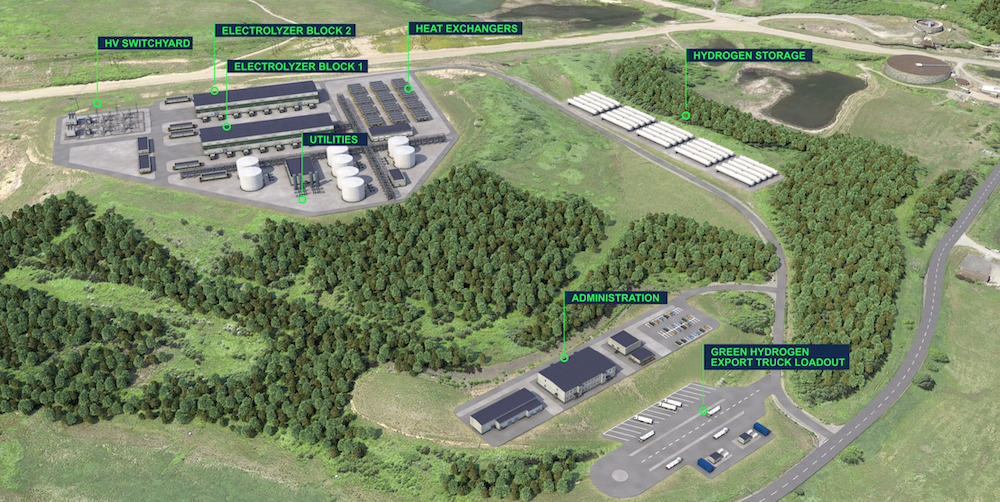

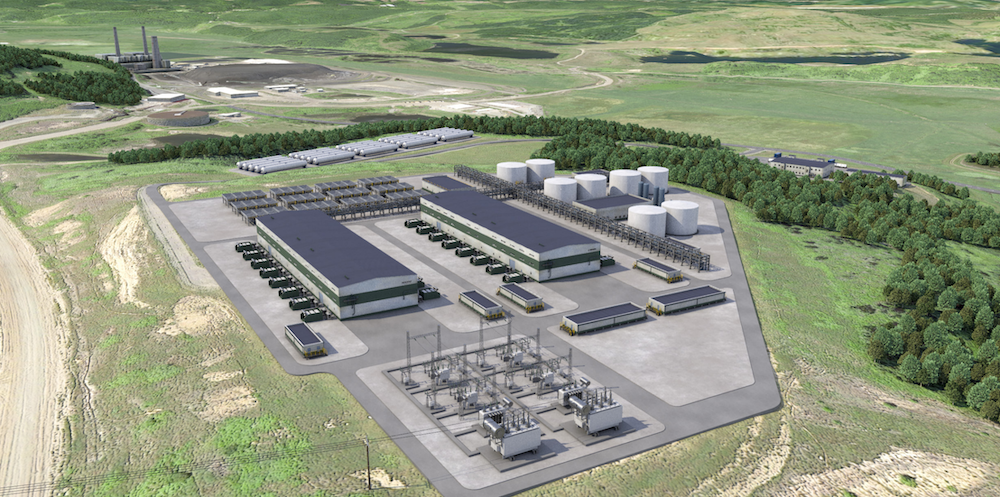

| pageLayoutLeft | EverWind Fuels selects Nel to participate in the FEED study for the Point Tupper project | 5/4/2022 1:40:29 PM | False | EverWind Fuels selects Nel to participate in the FEED study for the Point Tupper project | EverWind Fuels has announced that it has acquired the NuStar storage terminal in Point Tupper, Nova Scotia. | EverWind Fuels has announced that it has acquired the NuStar storage terminal in Point Tupper, Nova Scotia. | EverWind Fuels, a private developer of green H2 and ammonia production, storage facilities and transportation assets, has announced that it has acquired the NuStar storage terminal in Point Tupper, Nova Scotia. EverWind intends to expand and develop the Point Tupper site to be the location of a regional green H2 hub for Eastern Canada, including new green H2 and ammonia production facilities. These facilities will create new clean energy jobs, help support Nova Scotia’s carbon emissions reduction targets, and establish Nova Scotia as a global leader in the production of green H2 for domestic and export markets. “As part of the clean energy transition, we are proud to invest in Nova Scotia and support the province in unlocking the immense opportunity presented by green H2,” said Trent Vichie, CEO of EverWind Fuels. “The development of green H2 is an essential tool in the fight against climate change. Expansion of the Point Tupper site will support significant economic development in the region that can attract billions of dollars in new investment, create new jobs, and help make Nova Scotia and Canada global leaders in this exciting industry.” As an alternative fuel, green H2 produced at the site is expected to help provide a green fuel for Nova Scotia and support carbon emissions reduction by over 1 MMtpy by 2025. By 2030, the project could reduce domestic and international carbon emissions by more than 4 MMtpy through the production of green H2. The Point Tupper site is ideally positioned to produce green H2 as early as 2025, supported by significant existing in-place infrastructure. Point Tupper has an existing ice-free, deep-water port with 27-meter depth and two berths which can accommodate the largest vessels in the world. The port is the deepest in Nova Scotia and the surrounding region. In addition, the Point Tupper site has existing rail loading facilities and is adjacent to pipeline networks to support domestic and regional markets. Electricity transmission is available at the site as well as 7.7 MM barrels of liquids storage and abundant freshwater, which is adjacent to the site. The site is operated by a highly qualified, 70-person team trained to protect the surrounding environment and deliver safe operations. In addition, EverWind has engaged a world-class group of partners to support development of the initial phases of the project, including:

|

|

| pageLayoutLeft | Air Products to supply first Rotterdam green H2 filling station for trucks | 5/4/2022 2:36:32 PM | False | Air Products to supply first Rotterdam green H2 filling station for trucks | Air Products, Schenk Tanktransport and TNO are collaborating on an endeavor which will develop H2 trucks and a public H2 refueling station. | Air Products, Schenk Tanktransport and TNO are collaborating on an endeavor which will develop H2 trucks and a public H2 refueling station. | Air Products, Schenk Tanktransport and TNO are collaborating on the Clean H2 and Road Transport Project (CH2aRT), an endeavor which will develop H2 trucks and a public H2 refueling station. The project focuses on H2 in heavy-duty road transport and is subsidized by the DKTI transport scheme of the Dutch Ministry of Infrastructure and Water Management.

This project is in cooperation with the Port of Rotterdam to create the largest H2 refueling station in The Netherlands, initially supplying three zero-emission trucks from Air Products, Schenk Tanktransport and other early H2 adopters in the Rotterdam port area. Air Products will supply and operate the refueling station in the Botlek area and supply green H2 in an efficient and safe manner, while Schenk Tanktransport will use the trucks for its daily logistics operations. TNO will monitor the entire project and use the insights obtained for the further development and application of H2 in heavy-duty road transport. The allocated DKTI transport subsidy is meant to support projects for sustainable transport. The grant was created to accelerate these sustainable innovations in the transport sector. The project also contributes to the ambitions of HyTrucks, an international consortium of various parties, which aims to deploy H2 in heavy road transport on a large scale by 2025 with 1,000 H2-powered trucks in the triangle of Rotterdam, North Rhine-Westphalia and Antwerp. The parties, working under a memorandum of understanding, include not only Air Products but also port companies, transport companies, fuel station operators and truck manufacturers, among others. Kurt Lefevere, Vice-President Benelux, Germany and France at Air Products said, “This partnership is very positive for Air Products as it offers the possibility, as the world's largest producer of H2, to contribute even more to the necessary deployment of H2 in heavy-duty road transport. It is expected that H2 will help meet society's need to make transport more sustainable, based on zero or low carbon dioxide (CO2) emissions. The choice of H2 for heavy duty vehicles, compared with other technologies, allows for faster refueling, a greater vehicle range and the transport of heavier loads. The subsidy is evidence of the commitment locally and provides even further momentum to move forward. Our technology has been used in over 250 projects around the world. In addition, Air Products has decades of expertise and experience in H2 production, equipment, logistics and services.'' Boudewijn Siemons, COO Port of Rotterdam said, "All modes of transport, from shipping to road transport, must be CO2 neutral by 2050. H2 is a clean, viable alternative to diesel for freight transport. But then, of course, there must be refueling stations. I am delighted that Air Products is taking the lead in this respect by commissioning the first H2 filling station for trucks in Rotterdam within two years." Harry Schenk, Co-CEO Schenk Tanktransport said, "For Schenk Tanktransport, this collaboration is fully in line with the partnership with Air Products and gives substance to our aim to be a frontrunner as a sustainable and innovative logistics service provider. Schenk Tanktransport has been focusing on reducing CO2 emissions for years and its fleet now consists of an increasing number of trucks running on (BIO) LNG. For us, H2 as a fuel is the next logical step in making our company and our environment more sustainable and future-proof." Martijn Stamm, Director Market TNO Traffic & Transport said, "TNO's mission is to contribute to the achievement of the zero emission targets by accelerating solutions for sustainable powertrains. Trucks based on H2 fuel cells are one of the ways to achieve 100% reduction. TNO has many years of experience in monitoring and analyzing the reliability, maintenance and consumption of trucks under various conditions. In addition to this technical analysis, TNO also looks at driver acceptance and satisfaction, and analyses the opportunities, barriers and scenarios for scaling up in practice.” |

|

| pageLayoutLeft | Hyundai Motor, Advent Technologies to collaborate on high-temperature fuel cells | 5/5/2022 10:02:10 AM | False | Hyundai Motor, Advent Technologies to collaborate on high-temperature fuel cells | Advent Technologies announced a collaboration with Hyundai Motor Company to assess applications of Advent’s proprietary technology in supplying Hyundai’s high-temperature fuel cell needs. | Advent Technologies announced a collaboration with Hyundai Motor Company to assess applications of Advent’s proprietary technology in supplying Hyundai’s high-temperature fuel cell needs. | Advent Technologies announced a collaboration with Hyundai Motor Company, under which Advent and Hyundai will work together to assess applications of Advent’s proprietary technology in supplying Hyundai’s high-temperature fuel cell needs.

Dr. Vasilis Gregoriou, Advent’s Chairman and Chief Executive Officer (left), and Dr. Jong Kook Lee, Hyundai’s Executive Director (right), during the signing ceremony in Advent’s Headquarters in Boston

More specifically, Hyundai’s Executive Director, Dr. Jong Kook Lee, traveled to Advent’s headquarters to participate in an in-person ceremonial signing of the agreement with Advent’s Chairman and Chief Executive Officer, Dr. Vasilis Gregoriou. This ceremonial signing marked the first such event in which Advent has partaken with Hyundai. Dr. Vasilis Gregoriou, Advent’s Chairman and Chief Executive Officer said, “We are excited to work with Hyundai as they pursue a decarbonization strategy involving high-temperature fuel cells. Bringing green energy solutions to carbon-intensive applications is imperative for achieving climate goals, a fact that both Advent and Hyundai understand. We recognize the importance of this agreement by choosing to begin this cooperative relationship with an in-person, ceremonial signing ritual and underscore the close relationship that the companies plan to share over the course of the agreement, with the goal of advancing high-temperature fuel cell development.”

Dr. Jong Kook Lee, Hyundai’s Executive Director said, “Hyundai is delighted to take these steps with Advent to develop best in class high-temperature fuel cells. We look forward to working with Advent through this testing and development phase in the hope that it will unlock a key step for more widespread adoption of fuel cell technology in high-temperature applications. With this agreement, Hyundai takes an important step forward with a new partner and leader in the HT-PEM space.” |

|

| pageLayoutLeft | Clean Port & Logistics, HHLA create cluster to test H2-powered equipment | 5/5/2022 11:10:52 AM | False | Clean Port & Logistics, HHLA create cluster to test H2-powered equipment | Clean Port & Logistics (CPL) and Hamburger Hafen und Logistik AG (HHLA) have created a cluster to test H2-powered port logistics equipment. | Clean Port & Logistics (CPL) and Hamburger Hafen und Logistik AG (HHLA) have created a cluster to test H2-powered port logistics equipment. | Clean Port & Logistics (CPL) and Hamburger Hafen und Logistik AG (HHLA) have created a cluster to test H2-powered port logistics equipment. The collaboration is to drive forward the decarbonization of handling and transport processes.

This will support and accelerate both the achievement of market maturity and the integration into regular port operations. To reduce emissions in port handling and the associated logistics chains, the innovation cluster has the support of the Federal Ministry of Transport and Digital Infrastructure – with HHLA in charge of managing the cluster. CPL brings together equipment manufacturers as well as port and logistics companies with academic partners, producers of renewable H2, software companies and operators and manufacturers of storage tank locations. The parties cooperate nationwide to conduct research and practical tests into how H2 can be used in a reliable way to supply power to port technology and port logistics. The cluster carries out simulations and investigations and develops training concepts for this purpose. At the core of activities will be a test center for H2-powered equipment at the HHLA Container Terminal Tollerort in Hamburg. The cluster will be sponsored by the Federal Ministry of Transport and Digital Infrastructure as part of a national innovation program for H2 and fuel cell technology. The funding guidelines will be coordinated by NOW GmbH and implemented by Projektträger Jülich. Angela Titzrath, Chairwoman of HHLA’s Executive Board said, “Port handling and heavy goods logistics will make their contribution to climate protection and improving the quality of life in urban areas. The key element here is the decarbonization of logistics. That can also be achieved with the help of hydrogen as the operating energy. This is why I am delighted to be launching a cluster alongside committed partners to test this promising new energy source. CPL will provide an additional boost to the transformation process." The cluster will enable cooperation across sites and support many ports in their efforts for more climate protection. Michael Westhagemann, Hamburg Minister for Economic and Labour Affairs said, the importance of the cluster for Hamburg in an exemplary manner: “The port is a focus area of our hydrogen strategy, which also includes the application of hydrogen, particularly in intralogistics, as an important pillar. HHLA will gain valuable, cross-disciplinary experience from the project on how the fuel of the future can make a concrete contribution toward reaching Hamburg’s climate targets.” Johannes Daum, Managing Director for hydrogen, alternative fuels and batteries at coordinating company NOW GmbH said, “NOW looks forward to accompanying the CPL innovation cluster as part of the e4ports network. Through our network activities, we are already aware of the urgent need for action at ports concerning the energy transition, but we also know the commitment port companies have for pursuing this goal. With CPL, we will bring the concrete application of hydrogen in port logistics to a new level.” As part of CPL, HHLA has already agreed the first MoU for the delivery of H2-powered empty container handlers and terminal tractors with Hyster Yale Group, Inc. The units will be powered by Nuvera fuel cells. The delivery of the terminal tractor is planned for the end of 2022, followed by the empty container handler in early 2023. |

|

| pageLayoutLeft | Deutsche Bahn and Siemens Mobility present new H2 train, storage tank trailer | 5/5/2022 12:42:58 PM | False | Deutsche Bahn and Siemens Mobility present new H2 train, storage tank trailer | Deutsche Bahn and Siemens Mobility developed a next-generation H2-powered train, and a newly designed mobile H2 storage trailer. | Deutsche Bahn and Siemens Mobility developed a next-generation H2-powered train, and a newly designed mobile H2 storage trailer. | Deutsche Bahn (DB) and Siemens Mobility are continuing to drive the climate-friendly transportation transition in rail. The two partners premiered elements of their innovative complete system at the Siemens plant in Krefeld: The newly developed Mireo Plus H, the next-generation H2-powered train, and a newly designed mobile H2 storage trailer. The train and its new infrastructure are intended to replace diesel multiple-unit trains in commuter and regional transport and reduce rail-related CO2 emissions to zero.

The H2goesRail project is being funded as part of the National Innovation Program for Hydrogen and Fuel Cell Technology (NOW GmbH) with €13.74 MM by the Federal Ministry for Digital and Transport (BMDV). The funding guideline is coordinated by NOW GmbH and implemented by project lead Jülich. “In its coalition agreement, the federal government agreed to electrify 75% of the country’s rail network by 2030,” said Michael Theurer, Parliamentary State Secretary in the BMDV. “Here, alternative drives can help reduce emissions from diesel rail transport. This way, we’ll be able to operate virtually climate-neutral on rail routes where full electrification is not possible. The H2goesRail project will not only test the use of hydrogen for rail, but substantially advance the technology.” “Only with a strong rail system and alternative types of drives will we be able to make a significant contribution to the fight against climate change. The Mireo Plus H enables climate-friendly and emission-free passenger transport,” said Michael Peter, CEO of Siemens Mobility. “With the Mireo Plus H, we’ve developed the next generation of hydrogen-powered trains that offers a particularly long operating range and faster acceleration. Each delivered train can save up to 45,000 tons of CO2 over its service life of 30 years compared to corresponding travel with cars.” “For Deutsche Bahn, hydrogen trains are an important component on our way to achieving climate neutrality,” said Dr. Daniela Gerd tom Markotten, Member of the Management Board for Digitalization and Technology at Deutsche Bahn. “With our development of the mobile hydrogen filling station and the related maintenance infrastructure, we are showing that we not only can-do mobility, but technology as well. And exactly that is what is needed for providing the climate-friendly transport of tomorrow. Together with Siemens and the newly developed hydrogen train, we are creating an overall system which will take us another step towards phasing out diesel and enable the greening of the fleet.” As a two-car train, the Mireo Plus H for the H2goesRail project has an operating range of up to 800 kilometers, is as powerful as its electric multiple-unit counterpart, has 1.7 MW of traction power providing up to 1.1 m/s2 acceleration, and a top speed of 160 kilometers per hour. A three-car version has a range of up to 1,000 kilometers. One key element needed to make H2 technology competitive with diesel fuel in daily operation is a fast-refueling process. To provide this, DB has developed a new method that, for the first time, enables a H2 train to be refueled as fast as a diesel-powered train. This is an especially important factor considering the closely timed scheduling of DB’s regional passenger service. The fast refueling of hydrogen trains will make the technology competitive in daily operations. H2 trains have a particularly climate-friendly drive technology, since it operates emission-free with green H2 and emits only water vapor. In the H2goesRail project, for example, the H2 train will save around 330 tons of CO2 in one year on the Tübingen-Pforzheim route, compared to a diesel-powered train. In general, the Mireo Plus H can save 520 tpy depending on the route profile (calculated on mileage of 200,000 kilometers). The H2 will be produced in Tübingen by DB using green electricity taken directly from the overhead power line. To service the train, the DB maintenance depot in Ulm will be equipped accordingly. The Mireo Plus H will start testing in Baden-Württemberg in 2023. During its planned passenger service in 2024, the H2 train for the H2goesRail project with Deutsche Bahn will provide regular passenger service between Tübingen, Horb and Pforzheim and replace a diesel train. Siemens Mobility and Deutsche Bahn will also be showcasing the H2goesRail project and the Mireo Plus H at the InnoTrans 2022, the world’s largest trade fair for railway technology, being held in Berlin. Project details: H2 propulsion Mireo Plus H Filling station Rapid refueling Maintenance Passenger operations |

|

| pageLayoutLeft | Sponsored Content: Burckhardt Compression: Groundbreaking for the construction of a H2 test facility in Winterthur | 5/5/2022 1:27:07 PM | False | Sponsored Content: Burckhardt Compression: Groundbreaking for the construction of a H2 test facility in Winterthur | Burckhardt Compression laid the groundbreaking in Winterthur for the construction of a H2 test facility. | Burckhardt Compression laid the groundbreaking in Winterthur for the construction of a H2 test facility. | Burckhardt Compression laid the groundbreaking in Winterthur for the construction of a H2 test facility. It will serve the further development of sealing technologies and solutions for H2 refueling stations for heavy-duty vehicles.

Fabrice Billard, CEO Burckhardt Compression, Guido Kluth, Machinery Systems Manager Hydrogen Mobility Shell New Energies, Markus Vogt, Engineer, Engineering Office K. Vogt AG

Burckhardt Compression is one of the finalists selected by Shell New Energies as a partner for the development of oil-free high-pressure H2 compressors. Burckhardt Compression’s solutions for export and refueling applications will enable the compression of H2 gas up to 900 bar (as a booster) using non-lubricated compressors. “Hydrogen is an energy carrier with considerable potential, especially for heavy-duty applications,” said Fabrice Billard, CEO Burckhardt Compression. “We are pleased to continue researching these technologies together with Shell New Energies in order to contribute to the energy transition and the reduction of CO2 emissions. Our teams, together with Shell New Energies, have successfully completed the first technical milestones of the project and this new facility will allow us to test and optimize the new compressors before launch.” The test facility is expected to be operational by the end of 2022/early 2023, with testing to be completed by the end of the same year. |

|

| pageLayoutLeft | ScottishPower and Storegga form green H2 partnership | 5/6/2022 9:56:51 AM | False | ScottishPower and Storegga form green H2 partnership | ScottishPower and Storegga announced plans to build a series of green H2 projects in the Highlands. | ScottishPower and Storegga announced plans to build a series of green H2 projects in the Highlands. | ScottishPower and Storegga announced plans to build a series of green H2 projects in the Highlands. The initial project phases will be focused on the Cromarty Firth region (north of Inverness) and will provide green industrial heat across the region for a range of customers including distilleries and transportation sectors. The projects are expected to deliver hundreds of MW of green H2 production capacity before end of the decade, with plans for the first project to be operating by 2024. ScottishPower and Storegga have formed a partnership to develop, build and operate green H2 production plants across Scotland – with the potential to transform industry and transportation in the Highland region. The first project to be progressed will be the Cromarty Hydrogen Project, located just north of Inverness. The project is designed to deliver up to 20 tpd of green H2 from 2024 and has, subject to customer demand, the potential to scale to 300MW in a series of modular expansion phases. It will displace existing fossil fuel sources and enable the supply of green H2 into the heating processes of distilleries, with additional potential application to other local manufacturing, food production, and industrial heating applications. The Cromarty Hydrogen Project follows a successful feasibility study by ScottishPower and Storegga, undertaken in collaboration with major distillers Diageo, Glenmorangie, and Whyte & Mackay – all of which have operations in the Cromarty region. As part of meeting ambitious carbon reduction targets set by one of Scotland’s most valuable exporting sectors, the use of green H2 will decarbonize production processes, helping make Scotland’s national drink greener. Discussions on similar projects for other customers and industries are also underway. Green H2 has clear benefits in terms of security of energy supply. As well as accelerating the potential for cleaner industrial heating processes, green H2 is poised to transform the heavy transport sector across the country, with clean fuel potentially powering vehicles such as refuse collection trucks, buses, and HGVs. Green H2 is also a suitable alternative clean fuel for rail, air and shipping. Barry Carruthers, Hydrogen Director at ScottishPower said, “This is a really exciting milestone in our ambitions to support the growth of green hydrogen production across the country and the decarbonization of heavy industry. We can now get to work on turning plans on paper into tangible and deliverable projects that will transform industry in the Highlands – making a long and lasting difference for people, businesses and communities.” Andrew Brown, Head of Hydrogen at Storegga said, “The Cromarty Green Hydrogen Project is expected to be the UK’s largest green hydrogen facility when it commences operations in 2024 and is expected to rapidly expand thereafter. Storegga has been working with the distilling sector on the energy transition since 2014. In 2019, the Scotch Whisky Association’s Pathway to Net Zero report identified that hydrogen would play a key role in enabling Net Zero for the distilling sector. Phase 1 of the Cromarty Hydrogen Project is expected to be the first of many as we develop a broader green hydrogen manufacturing capacity in Scotland this decade. Storegga is proud to be working with ScottishPower and the distillers on this groundbreaking project.” |

|

| pageLayoutLeft | Study suggests solar energy can be cleanly converted into H2 | 5/6/2022 10:26:58 AM | False | Study suggests solar energy can be cleanly converted into H2 | Research led by the University of Strathclyde suggests that solar energy can be accessed and converted into H2. | Research led by the University of Strathclyde suggests that solar energy can be accessed and converted into H2. | Research led by the University of Strathclyde suggests that solar energy can be accessed and converted into H2.

Greenhouse gas (GHG) emission need to be significantly reduced to avoid potentially catastrophic effects of climate change, with access to clean and affordable energy needed to eliminate our reliance on fossil fuels. The UK Government plans to replace fossil fuels using H2, a storable fuel. Green H2 Most H2 is still made from natural gas, producing GHGs and green H2 production is urgently needed. Green H2 is produced from water using a photocatalyst – a material which drives the decomposition of water into H2 and oxygen using sunlight. The study, ‘Photocatalytic overall water splitting under visible light enabled by a particulate conjugated polymer loaded with iridium’ is published in Angewandte Chemie, a journal of the German Chemical Society. It suggests that using a photocatalyst under simulated sun light facilitates the decomposition of water when loaded with an appropriate metal catalyst - in this case iridium. When used in a fuel cell, H2 does not emit any GHGs at the point of use and can help decarbonize sectors such as shipping and transportation, where it can be used as a fuel, as well as in manufacturing industries. Solar energy “An abundant renewable energy resource to address the challenge of sustainable energy exists in the form of the Sun, with the energy reaching Earth's surface eight thousand times greater than the entire annual global energy need of our societies,” said Principal Investigator, Dr Sebastian Sprick, from Strathclyde. “The reported photocatalyst can access solar energy through energetically unfavorable processes to generate a storable energy carrier in the form of hydrogen from water. The hydrogen then can be converted cleanly into electricity in a fuel cell with water being the only side-product. “This study provides a way forward to optimize further as it is not sacrificial. The photocatalysts (polymers) are of huge interest as their properties can be tuned using synthetic approaches, allowing for simple and systematic optimization of the structure in the future and to optimize activity further.” Researchers say another potential advantage is that polymers are printable, allowing the use of cost-effective printing technologies for scale up - just like newspaper printing. Dr. Sprick said, “This will also be important to produce hydrogen at scale to address climate change effectively.” |

|

| pageLayoutLeft | ZeroAvia to expand U.S. base to test new components for H2-electric powertrains | 5/6/2022 10:53:16 AM | False | ZeroAvia to expand U.S. base to test new components for H2-electric powertrains | ZeroAvia has received its second twin-engine 19-seat Dornier 228 aircraft at its headquarters in Hollister, California. | ZeroAvia has received its second twin-engine 19-seat Dornier 228 aircraft at its headquarters in Hollister, California. | ZeroAvia has received its second twin-engine 19-seat Dornier 228 aircraft at its headquarters in Hollister, California. The new U.S. initiative will take the system developed in the UK HyFlyer II project and integrate it into the same type of aircraft. It will serve as the basis for testing new components and integrations, as well as a testbed for working with the FAA ahead of the ZA600 engine's planned certification in 2024. The company will test new components and integrations under an FAA certificate ahead of the ZA600 engine's planned certification in 2024.

The company will expand its U.S. base to test new components for the ZA600 H2-electric powertrains. With certification of the ZA600 planned for 2024, ZeroAvia’s second Dornier 228 aircraft to be retrofitted and tested in the coming months. The U.S. based aircraft will also be utilized to showcase several use cases for the company’s powertrains, including passenger, cargo, and industrial applications Val Miftakhov, CEO and founder of ZeroAvia said, “This new project in California will allow us to use architectures from our Hyflyer II initiative, where we are working with the same aircraft, and apply those lessons as we further test and demonstrate the system across a number of different use cases. Ultimately, this will help us optimize our zero-emission powertrain design ahead of certification. This year we will have two demonstration aircraft flying on two continents powered by our hydrogen-electric powertrains which will further help us secure partner and customer commitments across the worldwide aviation industry.” ZeroAvia will work towards a hybrid engine configuration that incorporates both the company's H2-electric powertrain and a conventional engine into the aircraft. The conversion is expected to take approximately 3-4 months to prepare the aircraft for test flights. After the engine is configured, it will enter the flight testing and demonstration program, spanning passenger, cargo, and industrial use cases with several to-be-announced partners. In addition to the launch of this program, ZeroAvia will be expanding its facility at Hollister to ensure adequate staff and resources to reach planned milestones. The company has added a new 15,000 square foot hangar to its footprint at the airfield, enabling space for conducting engineering work on the aircraft and its HyperTruck test bed platform, as well as ample office space to support its growing operations. Renee Wells, Executive Director of the Economic Development Corporation of San Benito County said, “There is huge potential for Hollister Municipal Airport to become a hydrogen hub. There will be significant demand and since California leads the world in adopting zero-emission vehicles, zero-emission flight infrastructure is the next natural frontier. ZeroAvia’s technology is an economically viable solution, and the EDC is thrilled to support them as they become the first TTF business development at the Airport, bring 50+ new jobs by year-end, and put Hollister on the map for innovative technology.” Last fall, ZeroAvia conducted the first program ground test of its HyFlyer II program and successfully tested the flight-intent 600kW powertrain with its 15-ton HyperTruck mobile ground testing platform. The HyperTruck, developed based on heavy-duty military trucks, is sized to also support testing the company’s larger planned powertrain (ZA-2000, with shaft power over 1.8 megawatt) which can be used to test systems for 40-80 seat aircraft. The HyFlyer II Project is co-funded by a £12.3 MM ($16.3 MM) grant through the UK Government’s ATI Programme. Progressing the demonstrations of the two Dornier aircraft is an important next step for ZeroAvia's sequential R&D pathway to realizing the transformational possibilities of moving from fossil fuels to zero-emission hydrogen as the primary energy source for commercial aviation. In the last quarter of 2021, ZeroAvia secured partnerships and funding with major airlines Alaska Air Group and United Airlines to accelerate the development of its ZA2000 engine, the largest of ZeroAvia's powertrain platforms, capable of producing between 2,000 kW and 5,000 kW. The company also recently announced their latest partnership with ZEV Station, where the two will collaborate to develop H2 refueling infrastructure at airports in California. ZeroAvia was also just named as a Bloomberg NEF Pioneer for its efforts to decarbonize aviation. |

|

| pageLayoutLeft | HAV Group receives preliminary approval for H2-based energy system for ships | 5/6/2022 11:10:09 AM | False | HAV Group receives preliminary approval for H2-based energy system for ships | HAV Group ASA has been granted preliminary approval for the H2-based energy system developed in the FreeCO2ast project. | HAV Group ASA has been granted preliminary approval for the H2-based energy system developed in the FreeCO2ast project. | HAV Group ASA has been granted preliminary approval for the H2-based energy system developed in the FreeCO2ast project. The approval is a major step towards the commercial use of H2 fuel by a commercial vessel.

“Hydrogen can be the key to achieve zero-emission shipping. This regulatory approval takes us an important step towards commercializing our hydrogen solutions and realizing the zero-emission ambition. The learnings from this comprehensive approval process are highly important for HAV Hydrogen’s competence in designing hydrogen system solutions,” said Kristian Osnes, project manager for the FreeCO2ast Project and managing director at HAV Hydrogen. Alternative design approval The Norwegian Maritime Authority has issued a statement of preliminary assessment which confirms that the alternative design is considered feasible and sound in accordance with IMO guidelines on alternative design (MSC.1/Circ.1455) and that the project is ready to advance into the final design phase. This means that HAV Hydrogen’s technology is ready to enter the commercial stage where the company can start offering its products to the global maritime market HAV Hydrogen is one of the first companies to receive this type of approval for a maritime H2-based energy systems with a liquid hydrogen tank below deck from the Norwegian flag. FreeCo2ast project HAV Hydrogen’s energy system is a spin-off from the groundbreaking FreeCo2ast project, which is currently developing a high-capacity H2 energy system that can be retrofitted onboard one of Havila Kystruten's coastal cruise ships. The FreeCo2ast project is supported by the Norwegian Research Council, Innovation Norway and Enova. Major project partners are amongst others Havila Kystruten and HAV Group's subsidiaries HAV Design, Norwegian Electric Systems and HAV Hydrogen, in addition to the research institutions Sintef Ocean and Prototech. The fuel cell manufacturer Powercell AB and tank system supplier Linde Engineering GmbH have contributed with knowledge and expertise in their respective areas. “The almost four years of cooperation with internal and external project partners in the FreeCo2ast project is obviously a major contributor towards the preliminary design approval. The ability to cooperate closely with highly experienced sister companies covering both ship design, electrical integration and hydrogen systems, gives us a competitive edge as a group”, adds Gunnar Larsen, CEO of HAV Group ASA. Next steps HAV Hydrogen will now enter the final design stage for its H2-based energy system. “We are now in a position where we can offer shipowners the necessary competence in selecting hydrogen system solutions and guide them through their approval processes, as well as delivering the marine zero-emission systems. The key is to align the right technology for the right need at the right time,” said Kristian Osnes at HAV Hydrogen. |

|

| pageLayoutLeft | Nel ASA receives purchase order for an alkaline electrolyzer system | 5/6/2022 11:45:11 AM | False | Nel ASA receives purchase order for an alkaline electrolyzer system | Nel Hydrogen Electrolyser AS has received a purchase order from an undisclosed Indian refinery for an alkaline electrolyzer to provide H2 for oleochemicals production. | Nel Hydrogen Electrolyser AS has received a purchase order from an undisclosed Indian refinery for an alkaline electrolyzer to provide H2 for oleochemicals production. | Nel Hydrogen Electrolyser AS, a subsidiary of Nel ASA, has received a purchase order from an undisclosed Indian refinery for an alkaline electrolyzer to provide H2 for oleochemicals production. Nel Hydrogen has received a contract for an alkaline electrolysis H2 production unit to be delivered to a leader in the production of oleochemicals. Oleochemicals are used in a broad range of products and industries, like metalworking lubricants, additives for plastics, rubber and paper production, automotive lubricants, greases and fuel additives, and personal care products such as soaps, lotions, cosmetics and deodorants. “This project represents an opportunity to showcase an electrolyser solution that provides reliable and cost-effective hydrogen for oleochemicals production. We are thrilled to be working with an established and respected leader in this sector,” said Tom Skoczylas, Sales Manager for Nel Hydrogen US. The purchase order has a value of approximately €2 MM, and delivery of the equipment is expected to be mid-2023. |

|

| pageLayoutLeft | Siemens Energy statement about joining President Biden for AM Forward initiative | 5/6/2022 5:04:41 PM | False | Siemens Energy statement about joining President Biden for AM Forward initiative | Rich Voorberg, President of North America for Siemens Energy, joined President Biden and a group of U.S. manufacturers at the United Performance Materials facility in Hamilton, OH to launch AM Forward. | Rich Voorberg, President of North America for Siemens Energy, joined President Biden and a group of U.S. manufacturers at the United Performance Materials facility in Hamilton, OH to launch AM Forward. | Rich Voorberg, President of North America for Siemens Energy, joined President Biden and a group of U.S. manufacturers at the United Performance Materials facility in Hamilton, OH to launch AM Forward (Additive Manufacturing Forward). AM Forward is an initiative designed to upgrade the capacity of America’s small and medium-sized manufacturers using additive manufacturing or 3D printing. “It was an honor to join President Biden and executives from other companies in the energy and aerospace industries this afternoon to kick off the implementation of AM Forward. We believe that for our company and for the industry to remain competitive, we must have a robust supply chain in the U.S. producing and processing critical parts and components for the energy sector. AM Forward will help accelerate the adoption of 3D printing at scale, increasing the agility and resiliency of our supply chain and supporting good-paying jobs across the United States. “Siemens Energy has been a pioneer and global leader in additive manufacturing for more than a decade. The company uses 3D printing at locations such as our Innovation Center in Orlando, FL, a global additive manufacturing hub that enables suppliers and customers to design, simulate, produce, and test prototypes using AM and other technologies. Because of our expertise, it was important to us to join the AM Forward initiative and continue to support suppliers in increasing additively produced parts, expanding training, accelerating standards development, and providing technical assistance. “Siemens Energy is proud to be part of AM Forward. We are excited to work with government leaders and other companies to invest in the future of American manufacturing.” |

|

| pageLayoutLeft | Topsoe signs joint declaration to ramp up manufacturing of electrolyzers | 5/9/2022 11:05:40 AM | False | Topsoe signs joint declaration to ramp up manufacturing of electrolyzers | Europe’s leading electrolyzer manufacturers agreed to increase their manufacturing capacity to reach 17.5 GW by 2025. | Europe’s leading electrolyzer manufacturers agreed to increase their manufacturing capacity to reach 17.5 GW by 2025. | Roeland Baan, CEO at Topsoe, said, “Power-to-X and energy independence will not happen in the EU unless we ramp up the manufacturing of electrolyzer in the EU as well. Therefore, I am extremely happy to see commitment from both the EU and industry to do exactly that.”

In Brussels, the industry committed to have 10 times as much combined annual electrolyzer manufacturing capacity in the EU by 2025 as is the case today – in return the EU committed to ensure a supporting regulatory framework and EU funds. Roeland Baan elaborates on the needed capacity,” If the EU wants to be independent of Russian gas – we need to produce 10 MMt of renewable hydrogen in the EU every year. Manufacturing electrolyzers must therefore be scaled up significantly. This represent both an unprecedented challenge and a significant opportunity for Topsoe.” The joint declaration features three pillars:

Under the Joint Declaration, Europe’s leading electrolyzer manufacturers agreed to increase their manufacturing capacity to reach 17.5 GW by 2025 and to further increase capacity by 2030 in line with projected demand for renewable H2. |

|

| pageLayoutLeft | Hexagon Purus Maritime receives inaugural order for H2 cylinders for maritime applications | 5/9/2022 12:03:30 PM | False | Hexagon Purus Maritime receives inaugural order for H2 cylinders for maritime applications | Hexagon Purus Maritime has received its inaugural order for cylinders to be used in onboard storage of H2 in maritime vessels. | Hexagon Purus Maritime has received its inaugural order for cylinders to be used in onboard storage of H2 in maritime vessels. | Hexagon Purus Maritime has received its inaugural order for cylinders to be used in onboard storage of H2 in maritime vessels. Hexagon Purus’ type 4 H2 cylinders will be used in onboard swappable storage containers for maritime vessels operating in the inland waterways in Europe. The value of the order is approximately €1.1 MM. Driving Energy Transformation “Our Type 4 high-pressure cylinders are at the core of what we do and with their corrosion resistance and long lifetime, the cylinders enable lower operational cost and total cost of ownership, which makes them ideal for maritime applications,” said Robert Haugen, Managing Director of Hexagon Purus Maritime. “This order represents an important commercial milestone for Hexagon Purus Maritime and lends further credence to our maritime strategy”. About the market Hexagon Purus combines maritime experience with extensive H2 storage expertise to provide a holistic approach to zero emission maritime solutions. Hexagon Purus is at the forefront of developing innovative H2 storage solutions with lightweight composite cylinders that are ideal for maritime applications. Hexagon Purus’ H2 storage and distribution business is well-positioned to support the ambitious energy transition required in the maritime sector - and to take a global leading role for integrated products in the emerging maritime H2 market. Together with partners, Hexagon Purus can cover major parts of the maritime H2 value chain. Timing Delivery of the cylinders are scheduled for 4Q 2022. |

|

| pageLayoutLeft | BEH2YDRO launches 100% H2 engines for heavy-duty applications | 5/9/2022 12:23:38 PM | False | BEH2YDRO launches 100% H2 engines for heavy-duty applications | BEH2YDRO will be launching its 100% H2 engines for heavy-duty applications. | BEH2YDRO will be launching its 100% H2 engines for heavy-duty applications. | At the World Hydrogen Summit in Rotterdam, BEH2YDRO will be launching its 100% H2 engines for heavy-duty applications. These innovative, zero emission engines are ready to use and will allow the industry to further engage in 100% sustainable and environmentally friendly development. BEH2YDRO is a JV between ABC and CMB.TECH.

After the successful launch of dual-fuel engines in September 2020, BEH 2 YDRO is now launching 100% H2 engines. Dual fuel engines Operating on 85% H2 gas and 15% conventional fuel, they make the owner or user less dependent on fossil fuels and reduce CO2 emissions by as much as 85%! They can also be used flexibly when H2 is (temporarily) not available. 100% H2 engines In recent years, however, BEH 2 YDRO has not rested on its laurels and has been working hard on an additional, completely new range of 100% H2 engines. The pioneering BEH 2 YDRO H2 engines deliver 100% clean energy. They emit no harmful emissions such as CO2, nitrogen, sulfur oxides or soot particles. In addition, they are non-toxic and:

They also have a long service life, thanks to an optimized air/gas mixture that reduces component heat-up. “With the launch of this monofuel hydrogen engine we are taking an important next step in the development of our BEH 2 YDRO engines. BEH 2 YDRO can now supply both dual fuel and mono-fuel hydrogen applications for a wide range of heavy industrial applications such as shipping, gensets, locomotives, etc. Thanks to BEH2YDRO we can already green a large part of the off-grid industry today,” said Alexander Saverys, CEO CMB.TECH. Power and utilization The innovative 100% H2 engine range has been developed for heavy duty applications and has a power range from 1 MW to 2.6 MW. These H2 engines are available in 6- and 8-cylinder in-line engines and 12- and 16-cylinder V-engines. As a main drive or in combination with an alternator, they are a reliable and 100% environmentally friendly source of energy for ships, drilling rigs or other marine applications. They are also ideally suited for driving locomotives. In addition, the BEH 2 YDRO H2 engines are extremely versatile because they have no problem with slight impurities in the H2. For example, they can also be used to recover waste H2 instead of flaring it. The BEH 2 YDRO 100% H2 engines use proven technology and are designed to ensure long term and efficient operation. In addition to their long service life, they are also very easy to maintain. This saves costs and time for owners and operators. |

|

| pageLayoutLeft | Advent Technologies co-signs joint declaration to increase electrolyzer manufacturing capacities | 5/9/2022 12:56:35 PM | False | Advent Technologies co-signs joint declaration to increase electrolyzer manufacturing capacities | Advent Technologies announced that its Chairman and CEO, Dr. Vasilis Gregoriou, participated in the European Electrolyzer Summit in Brussels. | Advent Technologies announced that its Chairman and CEO, Dr. Vasilis Gregoriou, participated in the European Electrolyzer Summit in Brussels. | Advent Technologies announced that its Chairman and CEO, Dr. Vasilis Gregoriou, participated in the European Electrolyzer Summit in Brussels. This event was organized by the European Commission in cooperation with Hydrogen Europe and took place under the auspices of the European Clean Hydrogen Alliance.

Commissioner for the Internal Market Thierry Breton, CEO of Hydrogen Europe Jorgo Chatzimarkakis, and 20 CEOs and executives representing companies including Advent, Bosch, Convion, Cummins, De Nora, Elogen, Enapter, Genvia, Green Hydrogen Systems, Helbio, H2B2, HyStar, John Cockerill, McPhy, Nel Hydrogen, Siemens Energy, SOLIDpower, Sunfire, Thyssenkrupp nucera and Topsoe, met and signed a Joint Declaration, establishing a clear goal of paving the way towards achieving the objectives of the REPowerEU’s proposed Hydrogen Accelerator, which sets out a strategy to double the previous EU renewable hydrogen target to 10 MMt of annual domestic production and an additional 10 MMt of annual H2 imports. Under the Joint Declaration, Europe’s leading electrolyzer manufacturers agreed to increase their manufacturing capacity to have, by 2025, a combined annual electrolyzer manufacturing capacity in Europe of 17.5 GW, as well as to further increase that capacity by 2030 in line with projected demand for renewable and low-carbon H2. Furthermore, the Joint Declaration features the three following pillars:

Dr. Vasilis Gregoriou, Advent’s Chairman and Chief Executive Officer, said “Today marked an important milestone for ensuring Europe’s long-term energy self-sufficiency and significantly reducing its reliance on fossil fuels. To achieve the goals outlined in the Joint Declaration that we signed today, the European electrolyzer manufacturing sector needs to enhance collaboration to ramp up electrolyzer production to approximately 25 GW per year with an installed electrolyzer capacity of 90-100 GW. We all recognize this as a challenge but also as a significant industrial opportunity that can positively contribute to Europe’s transition to clean energy at a far faster rate than ever before. Advent is highly honored to be part of this joint commitment, and we are delighted to see the Commission supporting the industry’s goal to boost electrolyzer manufacturing. All of us at Advent Technologies look forward to sharing our long-standing expertise and playing a key role in the scale-up of electrolyzer manufacturing capacity, aiming to secure energy self-sufficiency and help Europe meet the growing demand for renewable hydrogen.” |

|

| pageLayoutLeft | Delivery of the first Patriot units to Kimberley Clean Energy is underway | 5/10/2022 7:34:20 AM | False | Delivery of the first Patriot units to Kimberley Clean Energy is underway | The first payment to Renewables Plus has been made for the delivery of the initial Patriot unit to Kimberley Clean Energy at Kilto Station. | The first payment to Renewables Plus has been made for the delivery of the initial Patriot unit to Kimberley Clean Energy at Kilto Station. | The first payment to Renewables Plus has been made for the delivery of the initial Patriot unit to Kimberley Clean Energy at Kilto Station near Broome.

Project update:

Following this progress, we are well placed to see the unit arrive in the Kimberley mid-way through this year.

Once the unit arrives at Kilto Station, it will be assembled, tested and commissioned, with production expected to begin in the third quarter of 2022. This will be used to create clean energy for Kilto Station’s abattoir, irrigation and homestead complex, cutting their diesel usage by two-thirds. Initially, the modular H2 production unit will form part of Kimberley Clean Energy’s fossil fuel substitution strategy for Kilto Station. Once complete, the next stage will see a H2 system built across the various sites Kimberley Clean Energy is involved with. This will be achieved as we work with Kimberley Clean Energy to fulfil a MoU for 75 Patriot units. The goal is for the 75 units to decarbonize the entire value chain of the projects Kimberley Clean Energy is working on, while also developing baseload renewable power, green hydrogen, and fertilizer to support a cleaner future for the region. Kimberley Clean Energy will use this system as a proof of concept to seek additional power contracts over the next three to five years in the West Kimberley, which they hope will see a transformation to 100% renewable energy. Background to the Kimberley Clean Energy project Over the past hundred years, the Western Australian Kimberley region has observed a worrying transformation in its landscape and its effects have been devastating. To combat the region’s challenges, Kimberley Clean Energy has partnered with Patriot Hydrogen.

Kimberley Clean Energy has engaged Patriot to provide energy solutions that will enable a large-scale rehabilitation plan to restore its natural grasslands, create renewable power and aid economic development throughout the region. Research into West Kimberley has shown that the region was once known for its large and vast grasslands over 120 years ago. This is no longer the case today due to the domination of native Acacia Tumida and Acacia Eriopoda, which is also the cause of destructive bushfires. Patriot Hydrogen is working with Kimberley Clean Energy to provide the region with an energy solution that will use Acacia to produce green H2. Overall, Patriot Hydrogen’s goal is to partner with Kimberley Clean Energy to help protect their beautiful natural land, reduce fossil fuel usage and remove the risk of bushfires by turning the Acacia into green H2. |

|

| pageLayoutLeft | FuelCell Energy extends term of agreement with ExxonMobil for carbon capture technology | 5/10/2022 8:11:55 AM | False | FuelCell Energy extends term of agreement with ExxonMobil for carbon capture technology | FuelCell Energy announced that it has extended the term of its joint development agreement with ExxonMobil Technology and Engineering Company. | FuelCell Energy announced that it has extended the term of its joint development agreement with ExxonMobil Technology and Engineering Company. | FuelCell Energy announced that it has extended the term of its joint development agreement with ExxonMobil Technology and Engineering Company through December 31, 2022. The agreement will enable the companies to continue working to advance fuel cell CCS technology closer to commercialization and to explore market applications with a focus on three areas:

“Extending the scope of our long-standing agreement is evidence of ExxonMobil and FuelCell Energy’s joint desire to accelerate commercial deployment of differentiated fuel cell carbon capture technology,” said Jason Few, CEO of FuelCell Energy. “We are excited to build on the recent achievement of a key technical milestone as we advance toward the goals of a carbon capture demonstration and, ultimately, full scale deployment. We believe carbon capture is an essential requirement toward achieving global climate objectives.” “We are extending our agreement with FuelCell Energy to continue joint development of a novel technology that may accelerate deployment of carbon capture in industrial sectors,” said Prasanna Joshi, Vice President of ExxonMobil Technology and Engineering Company. “Carbonate fuel cell technology is part of our lower-emissions research and development portfolio as we look to identify commercially scalable technologies that can help reduce greenhouse gas emissions from vital sectors of the economy in support of a net-zero future.” |

|

| pageLayoutLeft | Lancaster, California announces partnership with Choshu Industries | 5/10/2022 8:33:54 AM | False | Lancaster, California announces partnership with Choshu Industries | The City of Lancaster, California, announced its partnership with Choshu Industries Corp. of America (CICA), a Yamaguchi. | The City of Lancaster, California, announced its partnership with Choshu Industries Corp. of America (CICA), a Yamaguchi. | (PRNewswire) – The City of Lancaster, California, announced its partnership with Choshu Industries Corp. of America (CICA), a Yamaguchi, a Japan-based R&D, solar energy power stations, environmental equipment, semiconductors and H2 technology and power solutions company. The partnership will initially seek to integrate Choshu's SHiPS, a containerized H2 production and refueling station system, and MizTomo, a stationary fuel cell power system, into the City's Green Energy Microgrid (GEM) system.